Engineering simulation has evolved from a specialized testing method into a foundational part of product development. Digital tools that once focused on basic stress testing can now model complete systems under real-world conditions. These tools allow teams to make better design decisions earlier, minimize costs, and accelerate timelines. Across industries, simulation has become essential to building innovative, safer, and more reliable products.

Faster Product Development with Digital Testing

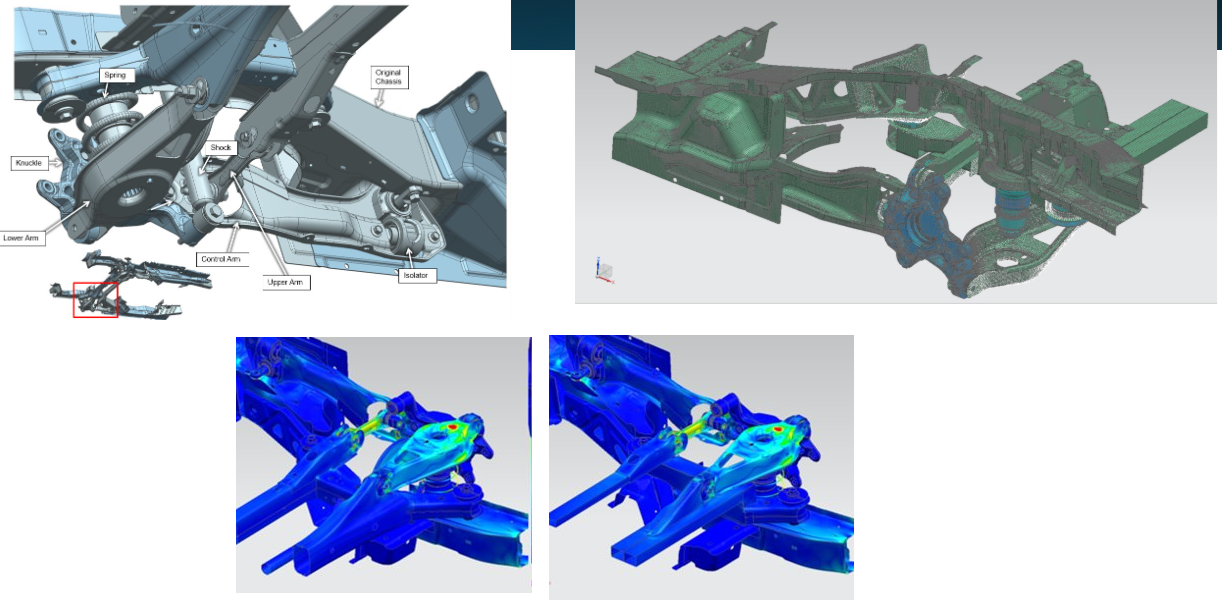

Simulation enables faster design cycles by replacing time-consuming physical tests with virtual evaluations. Engineers can quickly run digital models through various scenarios to uncover problems early. For instance, Finite Element Analysis helps teams validate load-bearing performance before prototyping even begins.

Instead of building and testing multiple physical versions, teams can refine designs through digital iterations. Early error detection shortens development timelines, reduces material costs, and enables teams to pursue more ambitious goals with less risk.

Improving Accuracy and Performance with Virtual Models

Modern simulation tools replicate real-world environments with impressive accuracy. Engineers can test how a design responds to heat, vibration, fatigue, and other operating conditions. This level of detail is especially valuable for equipment exposed to extreme loads or temperature shifts.

Simulation also supports advanced techniques such as multiphysics modeling and Computational Fluid Dynamics. These capabilities are important when products operate in complex environments or need to balance multiple performance objectives. Accurate simulations help avoid overdesign while ensuring the final product meets safety standards.

Enabling Innovation with Fewer Constraints

Simulation provides a digital environment where new ideas can be explored without the commitment of costly builds. Engineers can experiment with new geometries, materials, and design concepts more freely when testing takes place on a screen instead of in a lab.

This freedom fuels innovation. Teams can pursue lightweighting through topology optimization or test a novel mechanical configuration before committing to fabrication. Simulation gives engineers the confidence to push boundaries while managing risk.

Reducing Risk in Regulated Environments

Industries like aerospace, agriculture, and medical devices demand strict adherence to quality and safety standards. Simulation plays a critical role in meeting these requirements efficiently. Engineers can document how designs perform under required loads or operating conditions and use this evidence to support regulatory submissions.

Simulation also provides traceability and repeatability. Each result can be reviewed, stored, and verified in a broader quality management system. This ensures that development remains aligned with both internal standards and external compliance frameworks.

Real-Time Simulation and Embedded System Integration

Simulation is increasingly used not just in design but in system-level testing. Embedded simulation models can be integrated into hardware-in-the-loop setups to validate control systems and dynamic responses. This is especially useful for equipment that includes embedded software or real-time feedback loops.

By running simulations in parallel with real-world hardware, engineers can test how embedded systems will behave in changing conditions. This approach is valuable for fine-tuning performance and avoiding issues once the product is in the field.

When to Bring in Engineering Simulation Expertise

Many teams turn to external simulation experts to develop new product lines or address design challenges outside their core focus. Simulation support can also help meet aggressive timelines or manage risk on high-stakes projects.

Expert services include FEA, CFD, fatigue analysis, and embedded simulation systems. Partnering with specialists allows internal teams to move faster while maintaining confidence in results.

Simulation Can Help You Build Better Products

Simulation gives companies a measurable advantage by accelerating development, increasing reliability, and supporting innovation. As simulation tools become more powerful, the expertise required to use them effectively also grows. Today, simulation is more than just a testing method. It’s a strategic capability that informs better decisions throughout the product lifecycle.

RFA Engineering provides expert simulation support tailored to your goals, whether you’re validating early concepts or modeling complex systems. If your team is looking to reduce testing costs, improve reliability, or evaluate new design directions, working with experienced simulation engineers can help you move forward more confidently.