Modern product development is shaped by tighter budgets, shorter timelines, and rising performance expectations. As these pressures increase, engineering simulation has become an essential strategy for building reliable, high-performance products more efficiently. Tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) enable engineers to test, iterate, and refine designs virtually—long before physical prototypes are built. For companies focused on reducing costs, limiting design risks, and accelerating time to market, simulation has become a competitive differentiator.

Reducing Physical Prototype Costs

Physical prototypes require materials, tooling, labor, and time—resources that can add up quickly over multiple design iterations. By using simulation early in the development cycle, engineers can digitally validate how a product will perform under real-world conditions. This reduces the number of physical prototypes required and limits late-stage design changes, saving both time and money. Teams can evaluate strength, deflection, vibration, and thermal response virtually, identifying issues before anything is built.

Optimizing Design Through Iteration

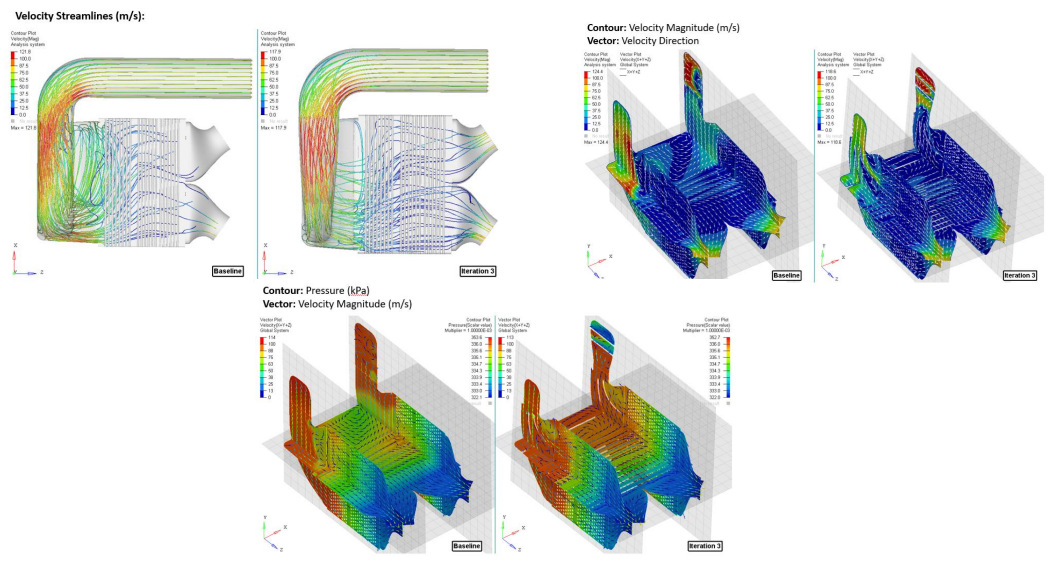

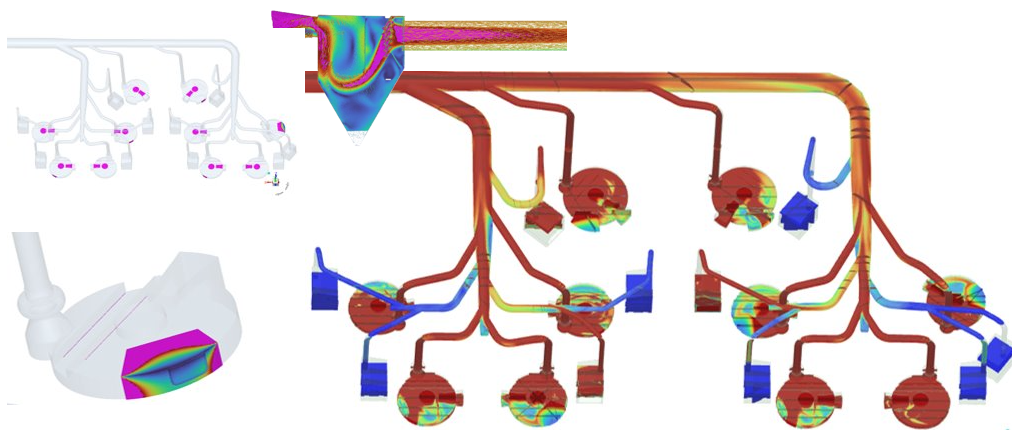

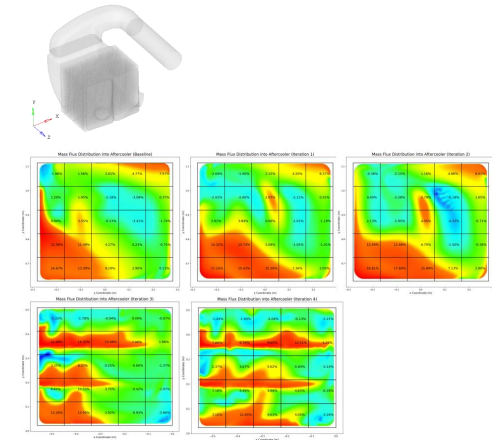

Simulation makes it possible to explore a wider range of design alternatives without incurring high physical testing costs. FEA and CFD allow dozens of digital concepts to be evaluated for structural strength, thermal efficiency, and aerodynamic performance. These virtual iterations help engineers arrive at an optimized design that meets both performance and cost targets. By improving early-stage decision-making, simulation helps avoid overbuilt solutions and supports leaner, more efficient designs.

Avoiding Late-Stage Rework and Tooling Costs

Design changes discovered after tooling is in place can result in production delays, wasted materials, and rework. Simulation mitigates this risk by uncovering stress concentrations, thermal problems, and fatigue points before designs are finalized. Identifying and resolving these issues in the virtual phase enables smoother transitions to manufacturing and limits disruptions later in the cycle.

Improving Performance and Reliability

Engineering simulation goes beyond reducing development costs—it directly contributes to product quality. FEA helps evaluate fatigue resistance, pressure tolerance, and vibration behavior. CFD enables better thermal management and fluid performance. These insights make it easier to balance strength-to-weight ratios, durability, and longevity, all of which reduce warranty claims and increase customer satisfaction.

Communicating Value Across Teams

Simulation results aren’t just for engineering teams. They provide visual, data-backed evidence that can be used across the organization. Design teams use them to justify material choices. Manufacturing teams use them to align production processes. Executives use them to weigh risks and make strategic decisions. Simulation creates a common framework that supports more transparent and confident product development across departments.

Integration and Documentation Efficiencies

Simulation platforms can be integrated into larger digital ecosystems like PLM, ERP, and maintenance management systems. When simulation outputs feed directly into these systems, traceability improves, and compliance documentation becomes easier to generate. Automating report generation and digital audit trails supports safety and certification requirements while reducing administrative overhead.

When External Simulation Expertise Adds Value

Advanced simulation techniques—such as nonlinear FEA, dynamic impact analysis, or multiphysics modeling—require specialized expertise. Not every team has the in-house capacity to apply these tools effectively. Partnering with simulation experts brings immediate value to projects that require deeper analysis or need to meet demanding timelines. External consultants can help validate designs, align with manufacturing requirements, and bridge software gaps without the need for long-term staffing changes.

Simulation Accelerates Innovation and Saves Costs

Simulation is more than just a validation step at the end of design. It is a strategic capability that helps teams reduce prototype cycles, minimize rework, and create more innovative products with fewer surprises. Whether you’re developing components for harsh environments or systems that must meet tight tolerance thresholds, engineering simulation can drive both performance and savings.

RFA Engineering provides simulation services that support every stage of development, from early concept validation to advanced system-level modeling. If your team is ready to reduce design risk, improve performance, or accelerate product development, we can help you harness the full value of simulation.