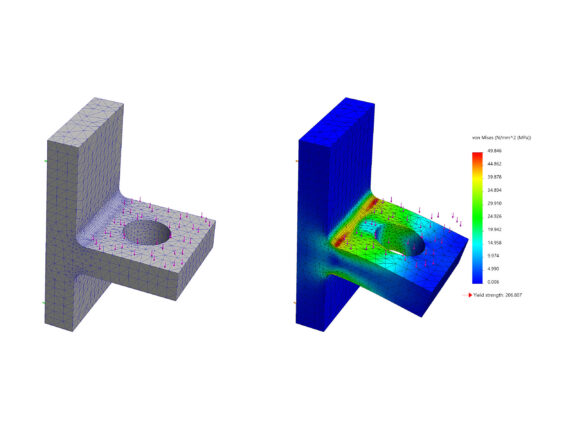

Finite Element Analysis

Static, dynamic, and fatigue simulations for structures and components—from welded frames to bolted joints and operator safety systems.

Accelerate product development with virtual testing that reduces prototypes, validates performance, and improves reliability.

Testing a physical product can add months and even years, plus costly expenses, to your project launch. At RFA, our skilled engineering simulation team can help reduce the cost of your prototypes and shorten your product design cycle.

With over 50 years of engineering experience in multiple industries, we can help you pinpoint any weaknesses in your design, diagnose field failures and identify potential mechanical failures. What’s more, we can optimize your design for improved safety and cost efficiency, helping you to drive your project forward.

Static, dynamic, and fatigue simulations for structures and components—from welded frames to bolted joints and operator safety systems.

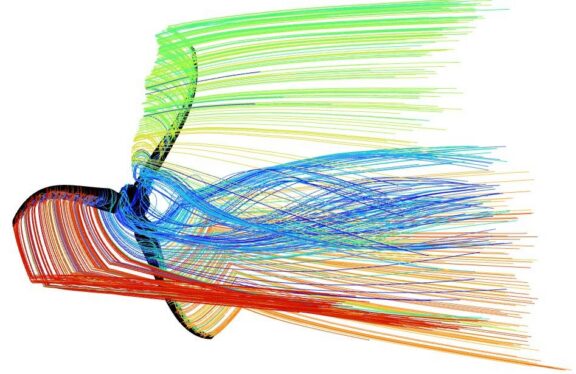

Thermal and flow analysis for cooling systems, HVAC, dust management, and fluid performance in demanding environments.

Analysis and testing of critical bolted joint connections to evaluate strength, design, and performance for safety and compliance.

Bridge the gap between simulation and testing — correlate simulation models with test data to calibrate and deliver reliable, high-fidelity models.

Whether you need structural analysis or design optimization, we prioritize your needs and goals from start to finish. Our agile, collaborative approach allows us to customize our services to your unique objectives and development process.

To ensure your project progresses efficiently, our dedicated team provides ongoing communication to keep you fully informed about your product’s simulation. No matter what challenges arise, we’ll use our innovation, diverse skill sets and real-world knowledge to design a cost-effective solution.

Our engineers understand the harsh demands of off-highway applications. We design and validate components built to perform under heavy loads, extreme conditions, and continuous use—delivering solutions that hold up in the real world.

With expertise across multiple simulation platforms, our senior engineers choose the right tools for each project. This flexibility ensures accurate results, efficient workflows, and insights that drive confident design decisions.

From agriculture and construction to defense and power generation, our cross-industry experience fuels innovation. We apply proven methods from one sector to another, optimizing performance, safety, and cost efficiency.

RFA’s analysts leverage a wide range of industry-standard tools: ANSYS, Simcenter 3D, Altair HyperWorks, nCode, CREO, Python, and MATLAB for scripting and data reduction.

Our team is ready to discuss your project requirements and deliver results that exceed expectations.