After completing the third stage of the product development process, you’re ready to enter the fourth stage: testing and validation. During this time, you’ll see your product in action on a small scale.

Testing & Validation: The Final Step Before Full Production & Launch

The fourth stage is also known as the “scale up” stage. You’ll test your product in a real market environment to validate the product itself, your marketing plans, production plans, operations and more. This stage is the final step before full production and product launch.

What Will You Need to Do During Testing & Validation?

The main goal of this phase is to gather customer input about your product to find any defects, design issues and major development concerns. During this phase, you’ll conduct a series of tasks:

- Plan the phase-out/in process of existing products: If your new product is replacing another product, you’ll need to plan for the phase-out of the old and phase-in of the new during this stage.

- Complete a “dry run” within a controlled environment: Although your product is basically complete, it will need to be tested in a controlled environment by trusted customer-partners.

- Update financial analysis based on part and process costs: Any changes to the production part and process costs will need to be updated within your final financial analysis to prepare for production.

A negative result at Gate 4 may result in design changes or a push of the product or service back into the development phase to resolve major issues. A positive Gate 4 result ends with product approval. With that approval, the product or service moves to full-scale production and complete market launch.

The RFA and Matrix product development process is a derivative of the Stage Gate® process.

Test & Validate Your Product With RFA & Matrix

Making it to the fourth stage of the product development process is something to be proud of. Yet, you must use this stage wisely to ensure your product is ready for market.

If you’re dealing with complications, RFA and Matrix offer product development support and consulting. To learn more about our services, give us a call at 952-843-2700 or send us a message.

Continue Reading

Choosing the Right Protocol in Software Engineering for Industrial IoT

Effective data collection is essential to modern industrial systems for supplying the data needed to train your Machine Learning (ML) and Artificial Intelligence (AI) models, as well as…

Read MoreAugment Your Engineering Team Through Flexible Outsourced Staffing

As engineering needs grow more complex, businesses face constant challenges in meeting specialized demands. Rather than hiring for every skill set, companies are expanding their expertise through outsourcing.

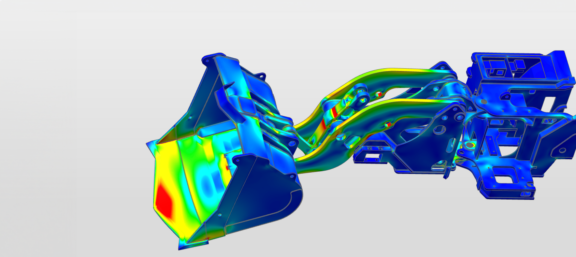

Read MoreAccelerating Innovation with Finite Element Analysis

Simulation has transformed how engineers approach design and development. Finite Element Analysis (FEA), a cornerstone of modern simulation tools, allows teams to create virtual environments for testing and…

Read More

Want to Learn More and Discuss Your Project?

We’re here to support you. Contact us today to get started.