Engineering teams face constant pressure to deliver innovative, high-performing products on tighter timelines. Design cycles are shorter, regulations stricter, and market expectations higher. Simulation technologies have become essential tools in navigating these pressures. By virtually testing and refining designs, teams can identify potential issues early, reduce reliance on physical prototypes, and improve collaboration across departments. Simulation is no longer an optional tool but a strategic advantage in modern product development.

How Simulation Reveals Hidden Design Issues

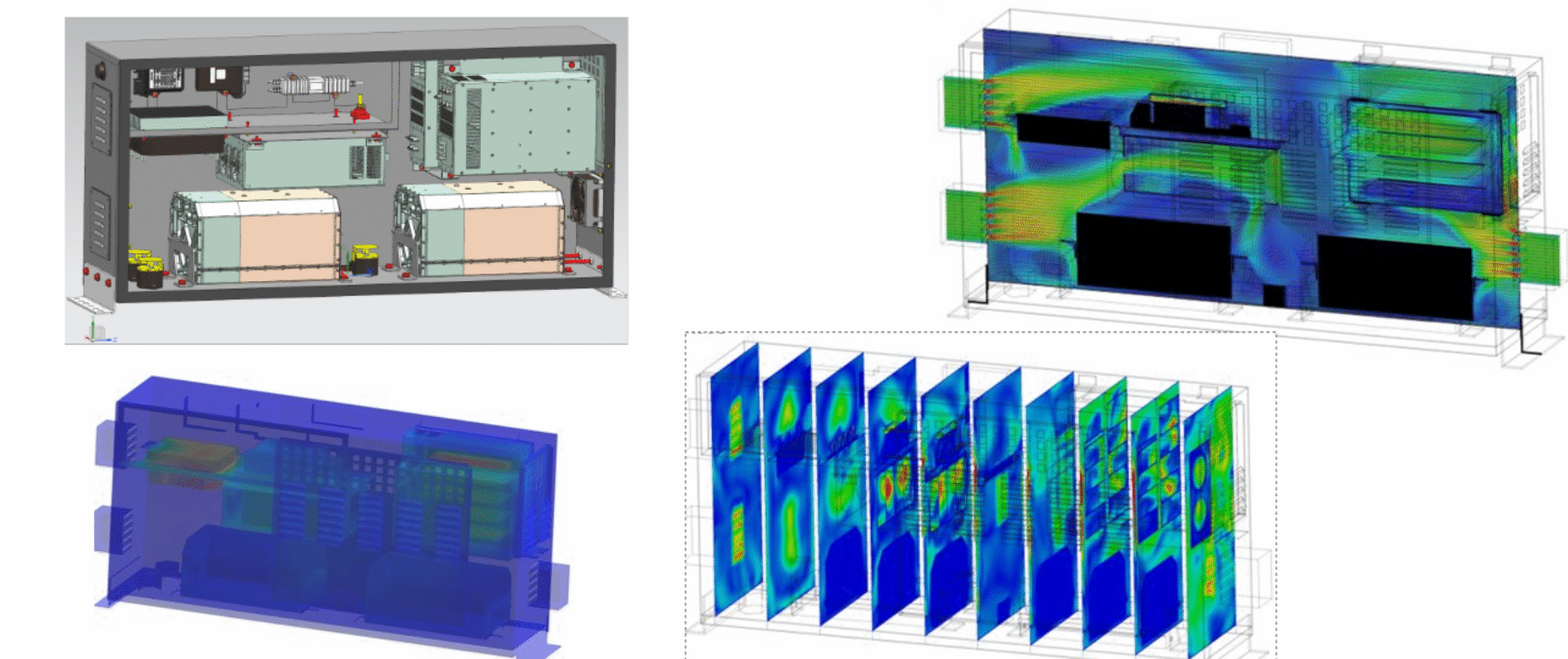

One of the greatest strengths of simulation lies in its ability to uncover performance issues that are difficult or impossible to see through traditional testing. Whether analyzing structural stresses, fluid dynamics, or thermal behavior, simulation gives engineers a deeper understanding of how their designs will perform in real-world conditions.

For example, Finite Element Analysis (FEA) can expose areas of weakness in a chassis under load, while Computational Fluid Dynamics (CFD) might reveal unwanted turbulence inside a cooling system. These insights guide design refinements that improve product safety, durability, and efficiency long before physical testing begins.

Accelerating the Development Cycle with Virtual Prototypes

Building and testing physical prototypes is expensive and time-consuming. Simulation allows teams to run virtual tests on digital models, drastically reducing the need for multiple physical iterations. This lowers costs and allows for faster exploration of alternative design concepts.

A single component can be evaluated under dozens of load cases in a fraction of the time required for physical testing. When integrated early in the process, simulation enables faster and more confident design decisions, helping products reach the market sooner.

Improving Collaboration Across Engineering Disciplines

Simulation helps break down barriers between different engineering teams. Mechanical, electrical, and software engineers can work from a shared digital model, evaluating how changes in one area impact the rest of the system. This is especially important for complex systems that include embedded controls, mechatronics, and thermal management challenges.

By offering a common language and framework, simulation tools improve communication and reduce the risk of late-stage surprises. When all teams can visualize and analyze the full system together, they are better equipped to align on design goals and make informed tradeoffs.

Meeting Regulatory and Performance Standards with Confidence

Product designs must comply with a growing list of regulatory and performance standards. Simulation helps verify compliance by allowing teams to test against requirements in advance. Whether evaluating crash safety, thermal limits, or fatigue resistance, simulation helps ensure that designs meet expectations without over-engineering.

For instance, Product Verification and Validation become more efficient when simulation has narrowed down the most likely failure points. This results in a smoother testing process and fewer design revisions late in the cycle.

Building Resilience into Complex Systems

As products grow more complex, the risk of system-level failures increases. Simulation provides a way to evaluate individual components and how they interact within the full assembly. This is particularly important in systems that rely on real-time data or embedded controls.

Engineers can build more robust systems by modeling how components behave under variable conditions or in failure scenarios. This proactive approach helps avoid costly recalls and builds trust with end users.

Take Control of Design Challenges with Simulation

Engineering simulation gives teams the tools to make smarter decisions earlier in the product development. Simulation improves outcomes and shortens timelines by helping uncover design risks, accelerate growth, and align cross-functional teams.

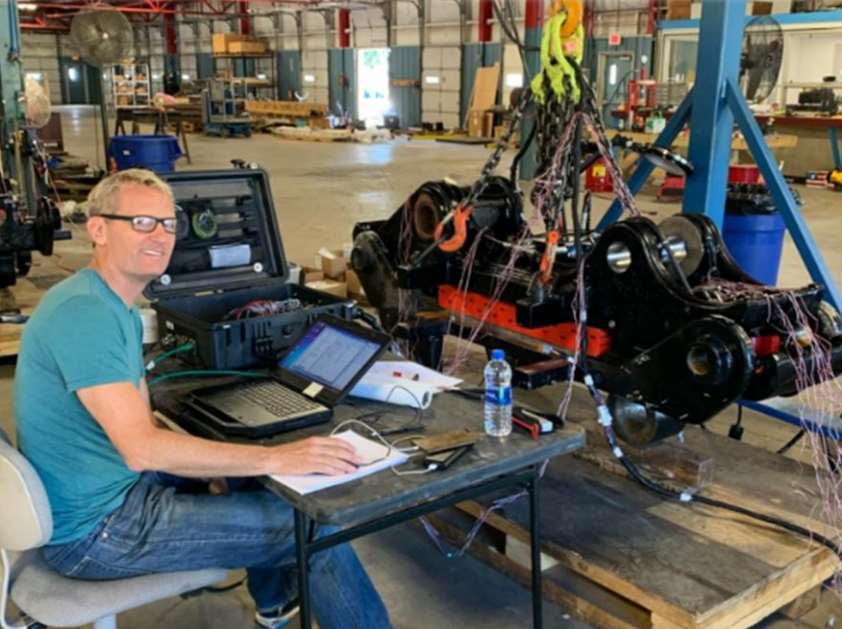

If you are developing complex products and want to reduce uncertainty, simulation can transform your design and delivery. RFA Engineering provides simulation expertise across industries, offering services from early concept validation to advanced system-level analysis. Whether you need to refine a design, improve reliability, or enhance performance, our team can help you confidently move forward.