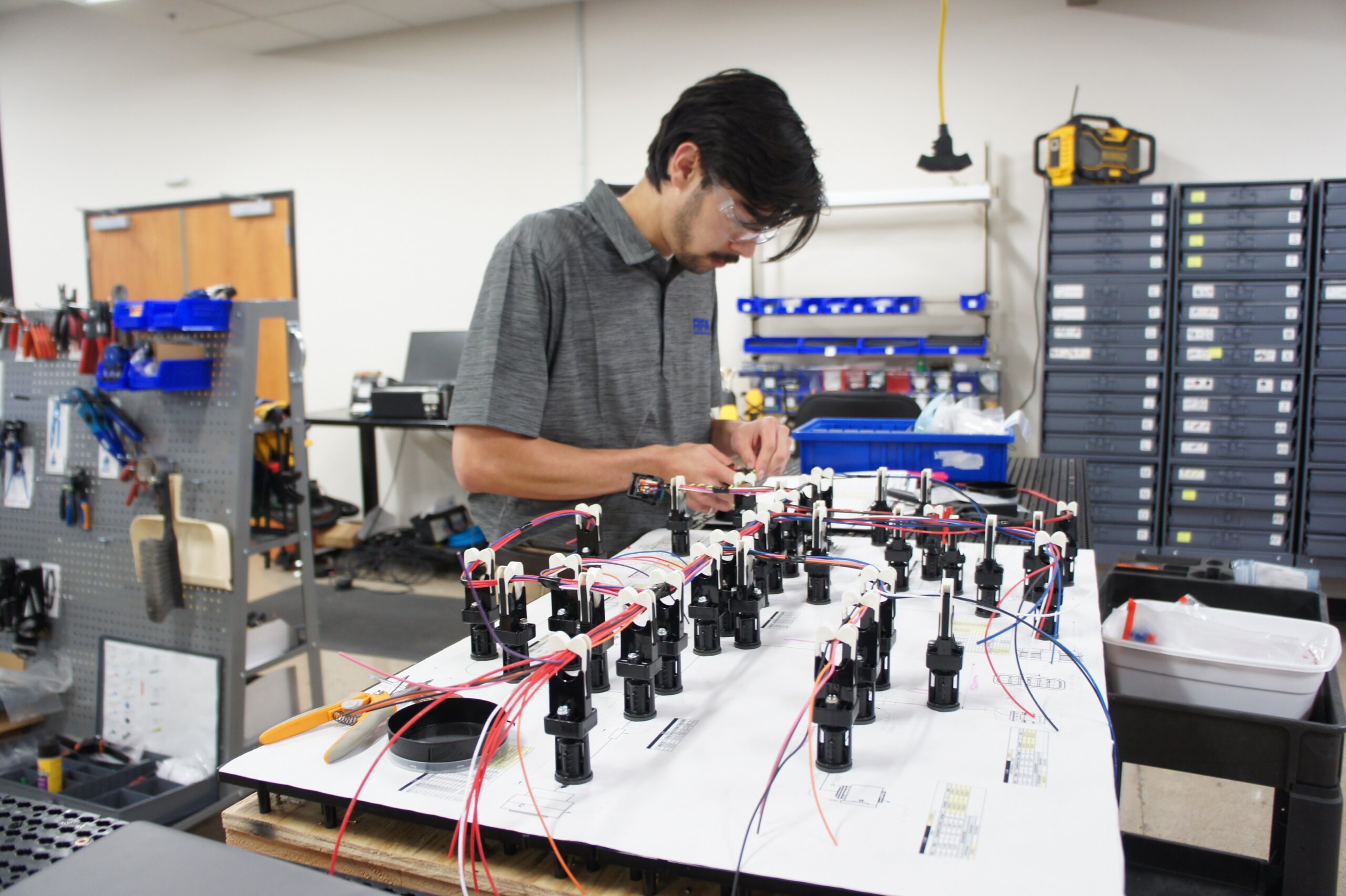

Custom Design & Engineering

Complete harness design and reverse engineering capabilities.

Custom wire harness engineering, design, and manufacturing for every stage of development.

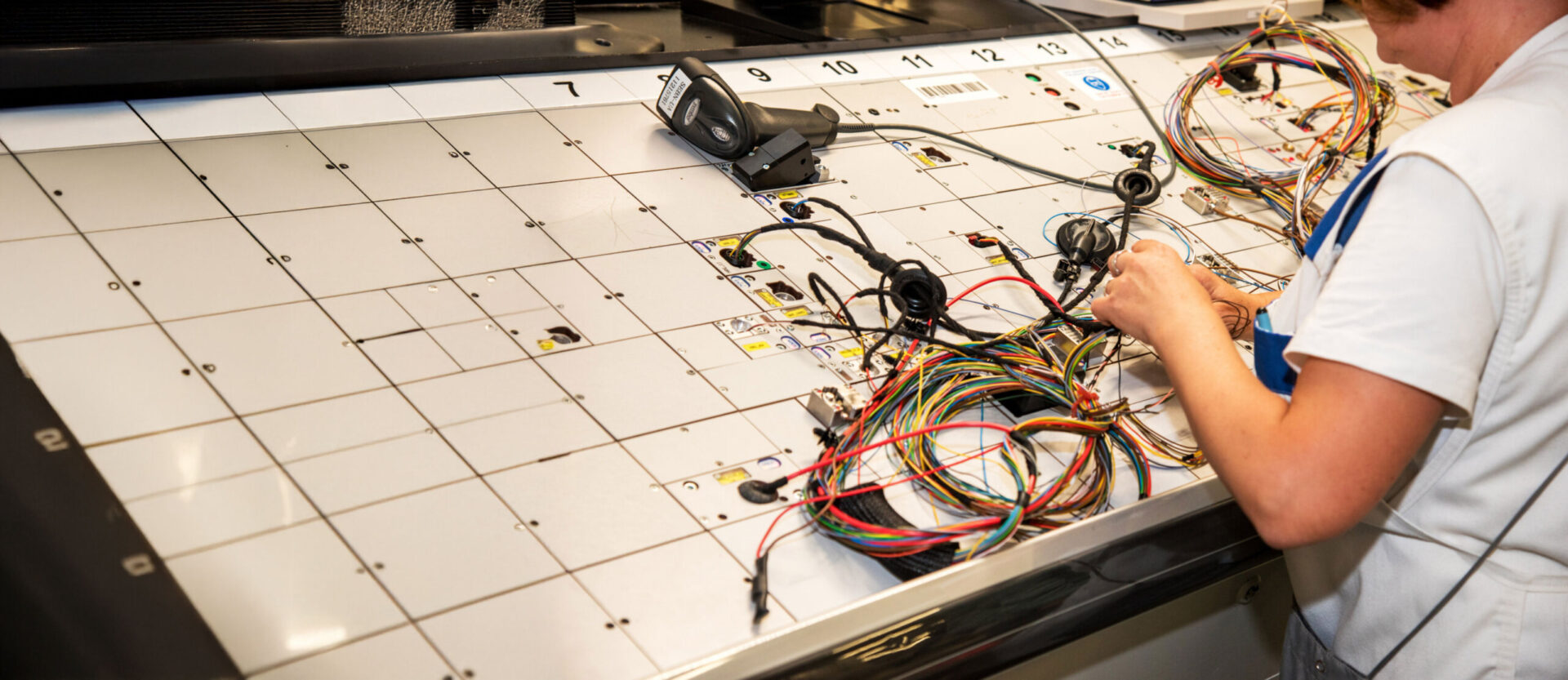

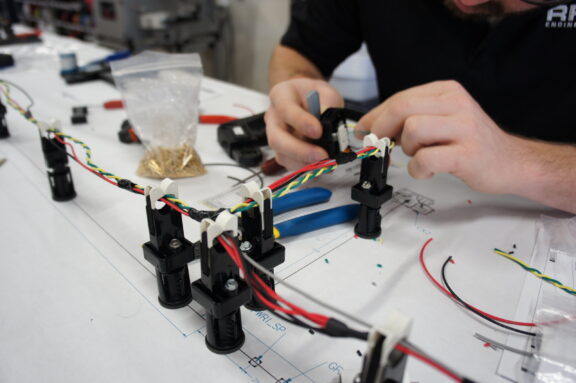

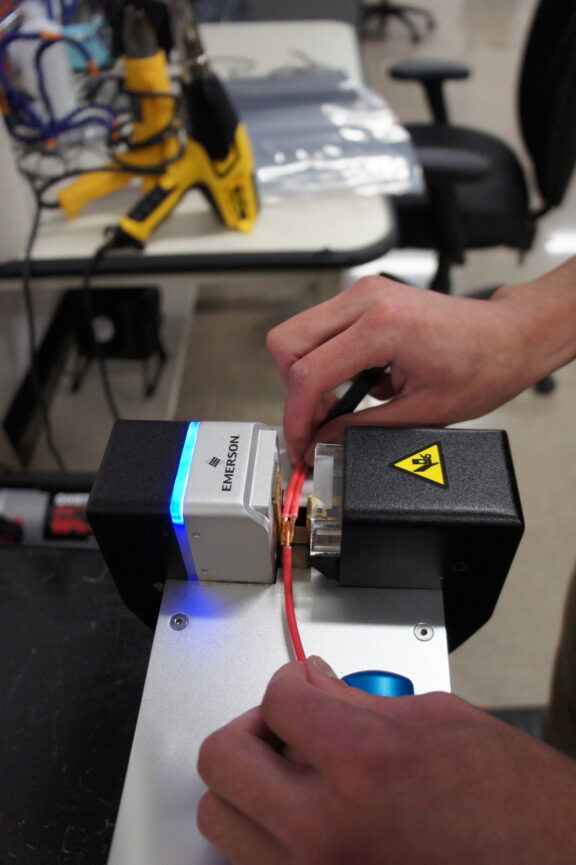

We understand how critical timing is. Whether you need prototype wire harnesses, wire assembly design, reverse engineering, or partial harnesses, we deliver comprehensive wire harness solutions. For time-sensitive projects, we specialize in rapid-turnaround prototyping and production-level small batches using advanced techniques like ultrasonic splice welding — delivering higher-quality weld joints, better process control, and lower energy usage compared to conventional methods.

Need custom wire harnesses on a tight deadline? Let’s discuss your timeline and specifications.

Complete harness design and reverse engineering capabilities.

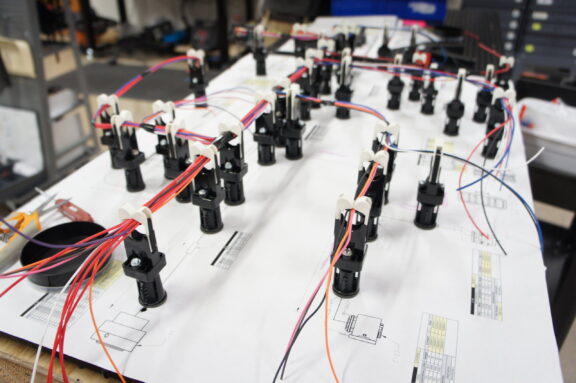

Pre-production harness builds for limited-run quantities.

Custom wire harness prototypes for testing and validation.

UV laser marking, ultrasonic welding, vinyl braiding, and more.

We engineer, design, and manufacture custom wire harnesses tailored to your exact specifications across industries ranging from aerospace and agriculture to medical devices and military applications. Our Eden Prairie, MN facility combines cutting-edge equipment and a skilled workforce to deliver exceptional quality on projects of any size or complexity. With deep industry expertise in regulatory requirements and real-world operating conditions, we design solutions that deliver the reliability and performance your applications require.

Our teams handle everything from simple looms to complex builds with capabilities including wire cutting, stripping, terminating, braiding, looming, and potting — all tailored to your specs and volume.

Every harness undergoes quality control, from continuity checks to full functional testing and advanced diagnostics using CableScan systems — ensuring performance, safety, and reliability under real-world conditions.

We utilize ultrasonic splice welding, heat shrinking, label wrapping, and laser-printed wire — delivering clean, repeatable results with minimized energy use and maximum consistency. Have a custom process or unique requirement? Let’s talk.

From OEM manufacturing to automotive, utility vehicles, and power sport vehicles, we support low-volume production with reliable, scalable harness solutions that prioritize performance and efficiency.

We understand the rigorous standards of aerospace, military, medical, oil & gas, and telecommunications applications — designing harnesses that are robust, compliant, and built to endure.

We offer flexible solutions for industrial equipment, robotics, agriculture, and custom new product development that meet complex routing requirements, emerging technologies, and evolving form factors.

Considering us for your next project? Request a sample harness to evaluate our build quality and performance standards. Complimentary samples available with no strings attached – see the difference for yourself.

Our team is ready to discuss your project requirements and deliver results that exceed expectations.