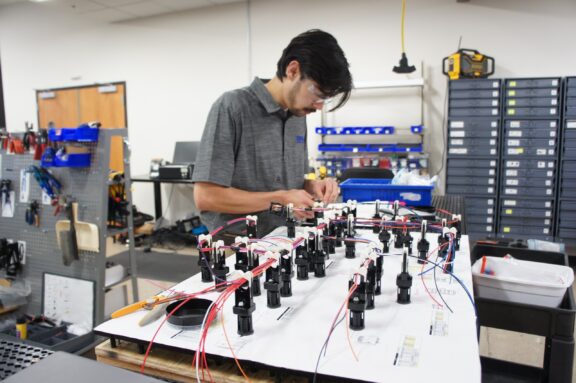

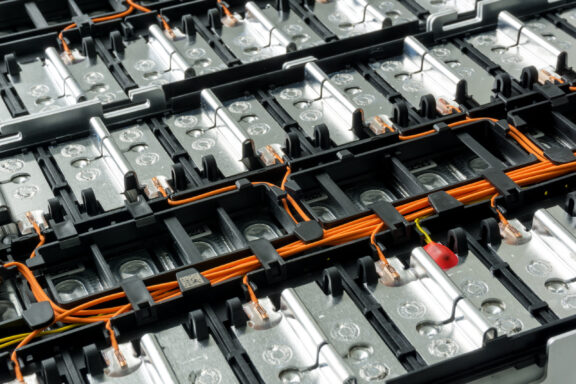

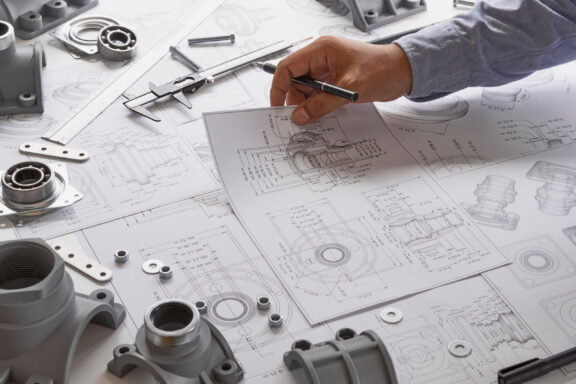

Mechanical Engineering

Our dedicated team can provide the skill sets to fill the entire spectrum of your mechanical development needs. From simple parts to complex systems, we can take your machine from concept to production and all the stages in between.